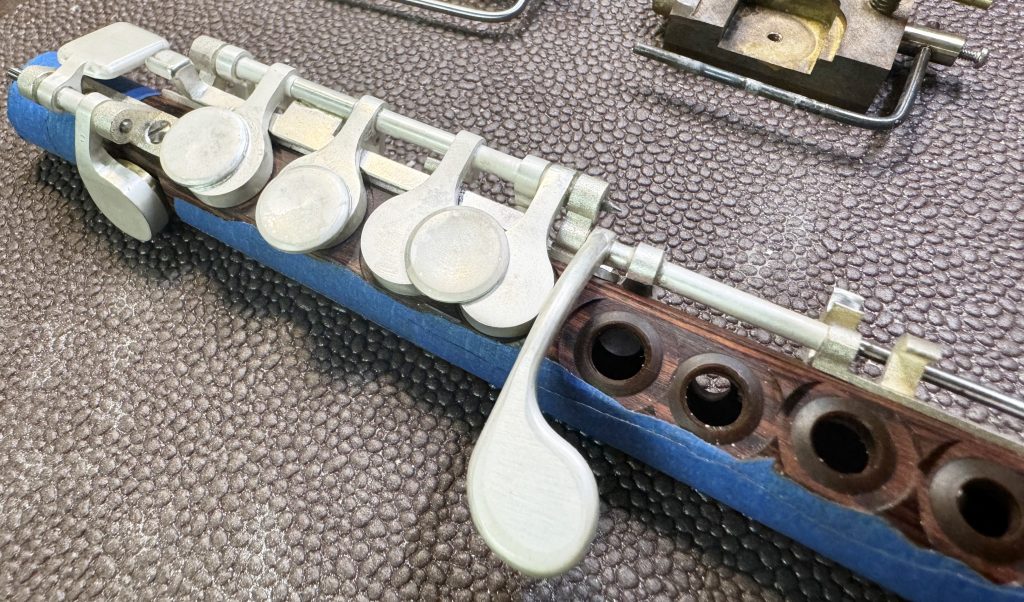

It has been six years since our last interview with Adam Pettry when he shared with us that he was going to start making piccolos. A lot has happened in the last six years! I’ve had the pleasure of watching Adam undertake this endeavor and even ordered my very own, all kingwood, Pettry piccolo. My piccolo arrived a few weeks ago and I couldn’t be happier to have this lovely new instrument. It is a voice that I have personally been searching for for many years. In the interview, Adam talks about the process of ordering and making a custom piccolo and he has shared some photos below of the process incase you want to get a closer look (btw, that is my piccolo in most of the photos). The interview link is below.

Interview Link “From Stick To Picc.”

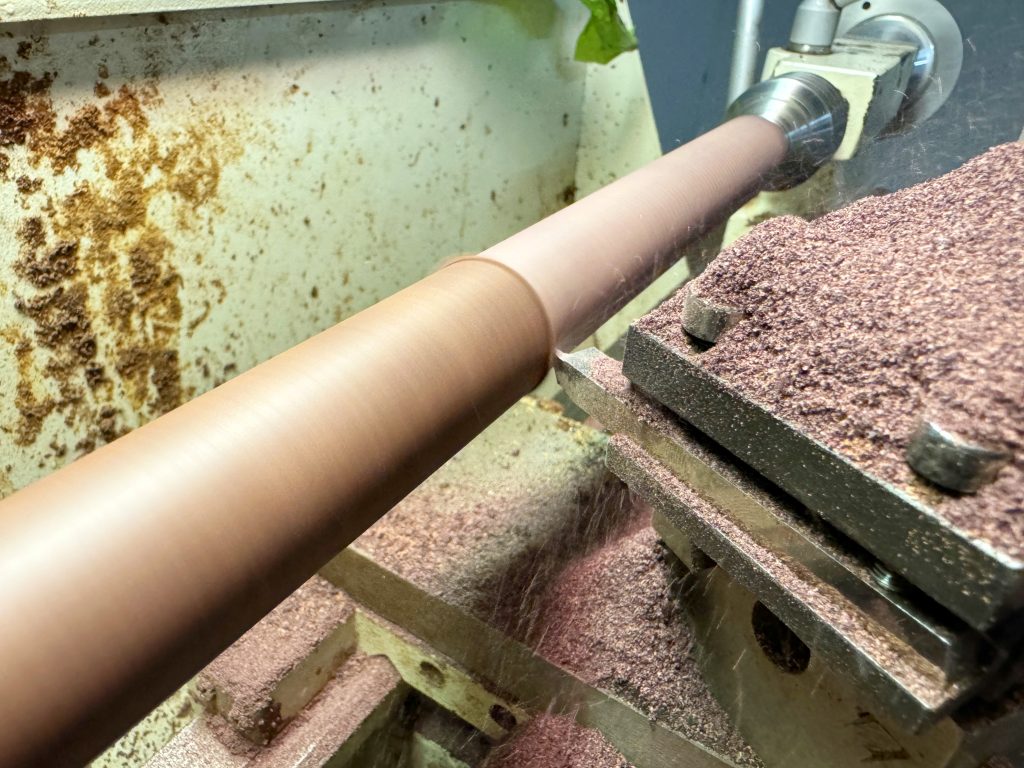

#2: Wood Processing: “ Wood is cut to appropriate lengths, and small cutoffs are saved for crowns. The pieces are turned round, drilled, and then open-reamed before a long resting period.”

Adam Pettry is the Founder of Pettry Piccolos, a custom piccolo manufacturing company in Atlanta Georgia. Internationally recognized as an artisanal piccolo and headjoint maker, his instruments can be heard on stages around the world, including multiple Grammy and Tony Award winning albums, artists, and ensembles. Adam pioneered social media advertising and education with his posts about instrument repair, leading to an explosion of new content from manufacturers and repair technicians around the world. His work as a social media influencer continued as a cast member of the iconic podcast ‘A Screw Loose’ which was the first of its kind.

Adam is also internationally recognized as a ‘Technician’s Tech,’ serving as a consultant, subcontractor, educator, and mentor to other manufacturers and repair technicians around the globe. In addition to making instruments, Adam is also an avid reader and writer.

Currently, Adam looks forward to sharing the eventual publication of his upcoming book on piccolo repair entitled ‘Piccolology: The Craft of Exorcising Deathwhistles.’

Great photo documentary of the piccolo-making process, Adam!